The inland rail project is a rail project linking Victoria with NSW and Queensland.

XRD and Petrographic Analysis Provide Critical Insights for Inland Rail Project

Inland Rail is a 1,600km freight rail line being built in Australia to connect Melbourne and Brisbane via regional Victoria, New South Wales and Queensland. It will provide a high-capacity, efficient rail link for moving goods between these cities and to ports, boost Australia's GDP, create jobs, reduce road congestion and improve safety.

Completion of the project requires extensive geotechnical investigations and materials testing to ensure the rail line is built on stable ground using suitable materials.

The Importance of XRD and Petrographic Analysis in Rail Projects

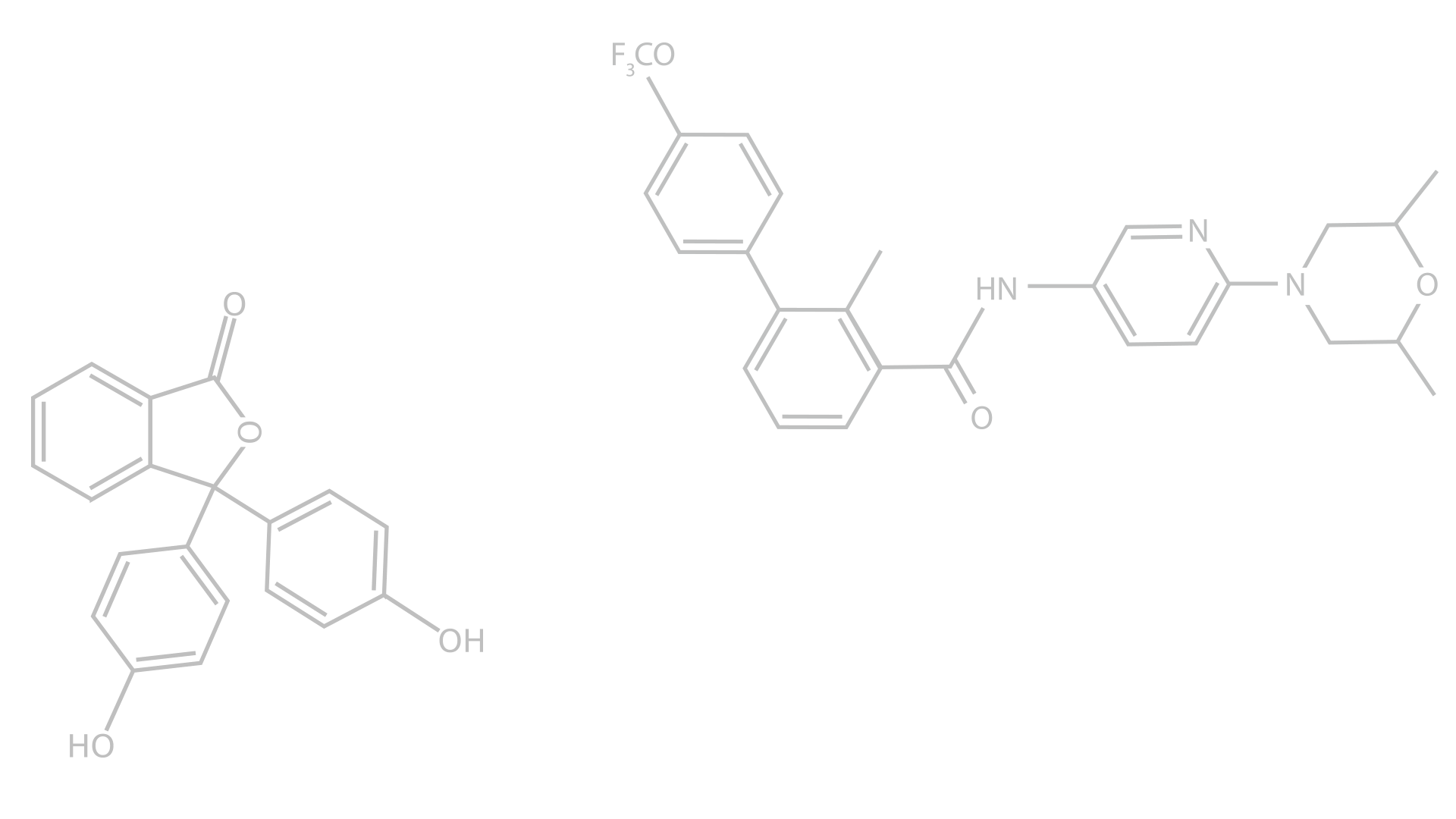

X-ray diffraction (XRD) and Petrographic analysis are two essential techniques used in major rail infrastructure projects like Inland Rail. XRD provides detailed information about the mineralogical composition of soil and rock samples, including the types and quantities of clay minerals present. This is critical, as certain clay minerals can cause instability and damage to rail lines if not properly accounted for.

Petrographic analysis involves examining samples under a microscope to assess their texture, structure, and mineral composition. This provides valuable insights into the engineering properties of the materials, such as their strength, durability, and reactivity to water and other substances. Together, XRD and petrographic analysis give engineers the information they need to select appropriate construction materials and design the rail line for long-term performance and safety.

Our Lab's Contribution to the Inland Rail Project

Our lab was contracted to provide specialized XRD analysis, including clay speciation, and petrographic analysis for soil and rock samples from the Inland Rail Project. Our team of experienced analysts used state-of-the-art equipment to precisely characterize the mineralogy of the samples, with a focus on identifying and quantifying the types of clay minerals present.

For the XRD analysis, we prepared the samples and analyzed them using our advanced X-ray diffractometer. We then interpreted the resulting diffraction patterns to determine the mineral phases present and their relative abundances. Our clay speciation process involved additional sample treatments and analysis to differentiate the specific clay mineral types, such as kaolinite, smectite, and illite.

We also performed detailed petrographic analysis on the samples using polarizing light microscopes. Our petrographers made thin sections of the samples and examined them under the microscope, documenting the mineral composition, grain size, texture, and any signs of weathering or alteration. They used this information to classify the samples and assess their suitability for use in the rail line construction.

Enabling Informed Decision-Making

The results of our XRD and petrographic analyses were compiled into detailed reports and provided to the Inland Rail Project's engineering team. Our work enabled them to make informed decisions about:

Selecting appropriate fill materials and aggregates for the rail embankments and track ballast

Identifying areas of expansive or reactive soil that require special treatment or excavation

Optimizing the rail line design and construction methods for the specific ground conditions

Ensuring the long-term stability and safety of the rail infrastructure

In summary, our lab's specialized XRD and petrographic analysis capabilities played a vital role in the Inland Rail Project. By providing detailed insights into the mineralogical and textural properties of the soil and rock along the rail corridor, we enabled the engineering team to make informed decisions and design a robust, durable rail line. Our work demonstrates the value that advanced analytical techniques like XRD and petrography bring to major infrastructure projects.